The Percy Program

It is a fight to level the playing field to be able to compete for jobs and careers on the basis of skills and make available apprentice training to all. In 1973 Al Percy launched a class action lawsuit to give workers like him a chance to better their lot in life. It would also ensure the availability of skilled workers to build the infrastructure of the future.

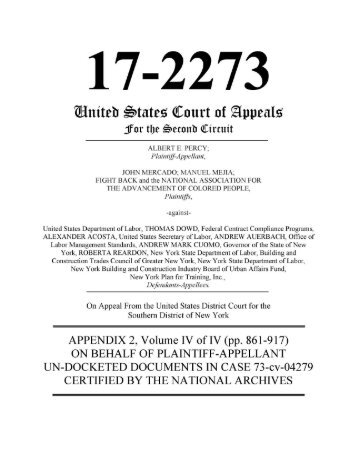

Percy Action

46. A Report of

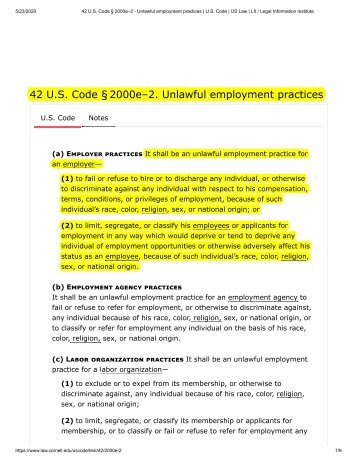

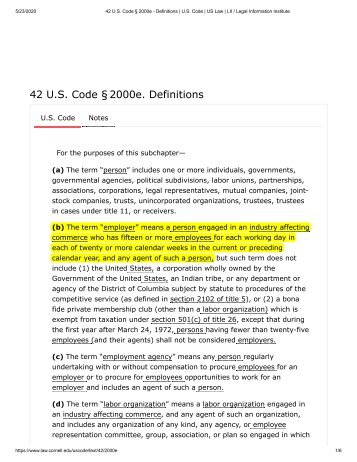

46. A Report of Examination of Oriska Insurance Company of June 15, 2012 (the “Report”) issued from DFS again alleged that Oriska was insolvent. 47. The issue of trustworthiness of management of Oriska, as raised at page 12 of the Report, was resolved and settled by the Stipulation and Judgment as set forth on at page 3 of the transcript that there was “no dishonesty or untrustworthiness” on the part of management of Oriska. 48. The Stipulation of accord and settlement on the record before the Court by the State and Oriska, is based on the Percy Program and is enforceable under CPLR 2104. 49. The Percy Program as an Alternative Employment Practice under the Civil Rights Act was developed specifically to address EO 11246, and it is intact and viable. Nevertheless, neither Percy nor other members of the Percy Class received or are receiving the relief contemplated by Judge Lasker in his decision of November 4, 1974. It is irrational and illogical to just assume that a business which is owned by a minority will, when awarded contracts as a goal, will then out of the goodness of their heart hire their ilk. No, even they want to hire skilled workers able to make their businesses profitable. Hiring is because of a person’s skills and capability, not because of the color of a person's skin or their ethnicity. 50. Technicians must be able to use the tools necessary in order to yield the best results in relation to the skilled crafts. This can only happen by having the best trained craftsman with specialized skills, training and experience in the industry. Specialized personnel, required to work in extreme and often isolated work conditions and locations must maintain safety and responsibility under harsh conditions and must be able to use material, equipment and innovation in planning and organizing. Trained personnel, materials and equipment are necessary to maintain facilities relied on by the general public for basic everyday needs of clean water, sewage treatment and electrical power distribution. Trained personnel must be knowledgeable in safely using structural materials to deliver those utilities by pipe, conduit, component parts, pumps, controls, belts, and knowledgeable in the mechanics of materials and methods utilizing pressurized systems and pneumatic tools, exposed to blood borne pathogens and virulent viruses now of great concern. 12

51. There are a wide variety of specialized jobs in many diverse industries requiring highly skilled employees, dependent on the ability of members of a team to properly produce results with a qualified team of technicians, mechanics, and engineers. 52. Working on a team under special circumstances alongside an experienced journeyman, an apprentice finds out what it takes to get the job done and move up in rank to more sophisticated and higher-paying jobs, possibly eventually becoming supervisors, owners of businesses or industry leaders as a result of their valued experience. 53. Everyone starts out at the bottom of the ladder in a scale of pay commensurate with entry level positions, experiencing all the duties and responsibilities beginning with the basics of cleaning up and setting up for work processes. There are long work hours and the work is generally hard but the pay is good starting out. Then, with the proper training, promotion to higher-paying and more responsible positions, which occurred for me in a relatively short period of time. 54. Mechanical tasks are needed to take care of equipment and facilities, checking for faults and leaks in pipes and fittings, using manual wrenches, compressed air tools and installing, starting up, repairing and maintaining pump and engine parts that are needed to service the utilities which the public relies upon, but take for granted. All of the jobs work as teams or with experienced craft persons. Even an entry-level worker must have good knowledge of mechanical systems, be skilled at working with hand and power tools, as well as able to repair any tool that breaks. Training in safety protocols and emergency procedures is an absolute must. Knowing how all equipment and systems work and the importance of knowing production methods is essential, along with the ability to check and maintain systems and machinery daily, while on the job, for upkeep and maintenance. 55. Many jobs depend on the way that teams are set up under the supervision of a skilled journeyperson, manager or tool-pusher. Responsibilities include getting the work done safely, efficiently and within regulations set down by government and company authorities. The work requires excellent organizational skills, communication and listening skills to be capable of working quickly with an eye for detail. A worker who is new to a worksite 13

- Page 1 and 2: THE APPRENTICE PRIVATE ATTORNEY GEN

- Page 3 and 4: The dilemma Lincoln was facing was

- Page 5 and 6: in the compromise of 1877 which end

- Page 7 and 8: often unable to keep their jobs and

- Page 9 and 10: Available Less Discriminatory Alter

- Page 11 and 12: UNITED STATES DISTRICT COURT for th

- Page 13 and 14: accepting Defendant New York State

- Page 15 and 16: ceased and the US withdrew from Sou

- Page 17 and 18: compliance with the New York State

- Page 19 and 20: A, Pt. 29 and Pt. 30. (the Fitzgera

- Page 21: y Secretary of Labor Herman in Apri

- Page 25 and 26: 60. There are many paths of advance

- Page 27 and 28: 72. We (myself as Class Counsel, th

- Page 29 and 30: The New York State Department of La

- Page 31 and 32: 04279, Appendix 1, Volume 1, page 5

- Page 33 and 34: known as the National Apprenticeshi

- Page 35 and 36: 100. The Percy Program (XVI. THE PE

- Page 37 and 38: which was done at Docket #96-104 in

- Page 39 and 40: economic and social injury and dama

- Page 41 and 42: Department as a mechanic at the Cen

- Page 43 and 44: 125. Percy was not promoted, remain

- Page 45 and 46: seek for which this action has been

- Page 47 and 48: education, skills development, trai

- Page 49 and 50: XI. The Advocates ALTERNATIVE EMPLO

- Page 51 and 52: 158. The Percy Program first presen

- Page 53 and 54: REGULATORY APPROVALS OF PERCY PROGR

- Page 55 and 56: on behalf of the Percy Class applie

- Page 57 and 58: The Percy Program Presented to the

- Page 59 and 60: States of America, and of rights se

- Page 61 and 62: 196. The apprenticeship program por

- Page 63 and 64: wages and lost opportunity along wi

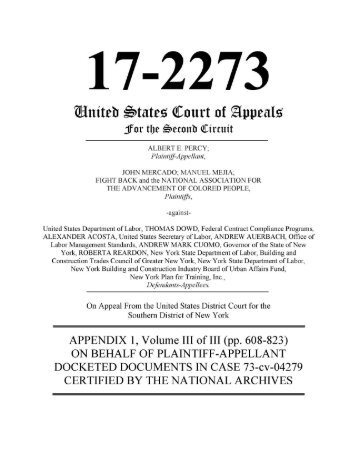

- Page 65 and 66: 214. In Case 73-cv-04279, Percy sou

- Page 67 and 68: Percy Class when the State proffere

- Page 69 and 70: willing and able to work, , and dam

- Page 71 and 72: apprenticeship programs. The Percy

- Page 73 and 74:

clean their work surfaces. Working

- Page 75 and 76:

negative pressure, positive pressur

- Page 77 and 78:

temperature & humidity of the work

- Page 79 and 80:

systems), the ordering process (e.g

- Page 81 and 82:

decontamination work area, mechanic

- Page 83 and 84:

employee information and training,

- Page 85 and 86:

mitigate the hazards are emphasized

- Page 87 and 88:

Lead Worker EPA 270. Lead hazard co

- Page 89 and 90:

compensation carrier that is also a

- Page 91 and 92:

The maximum amount that a multiple-

- Page 93 and 94:

Annual Standard Premium which is as

- Page 95 and 96:

of audited standard premium. Amendm

- Page 97 and 98:

State’s offer of EO 45, but EO 45

- Page 99 and 100:

XXVI. AS AND FOR A FIFTH CAUSE OF A

- Page 101 and 102:

the availability of the singular cr

- Page 103:

disenfranchised, and, pray that thi

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...