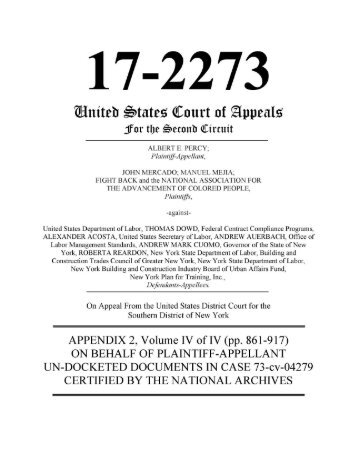

The Percy Program

It is a fight to level the playing field to be able to compete for jobs and careers on the basis of skills and make available apprentice training to all. In 1973 Al Percy launched a class action lawsuit to give workers like him a chance to better their lot in life. It would also ensure the availability of skilled workers to build the infrastructure of the future.

Percy Action

254. Verification

254. Verification procedures to ensure accountability (e.g. initialing the printout): unloading sterilizer, what compromises sterility (e.g. cooling time, temperature, handling, equipment failure), traffic flow (e.g. cart placement), test results, proper handling & incubation of the biological tests/process challenge devices, quarantine (e.g. implants, early release), interpreting & document test results, potential process failures, identify a process failure (e.g. wet packs, color change, failure to meet sterilization parameters), procedure for follow-up after process failure (e.g. recall, documentation, contact), load control (lot) number, required information for a load control (lot) number, documenting sterilization load contents, how & what to record (e.g. computer or manual load log sheet), rationale for documentation (e.g. recall, traceability), customer relations, customer relations, communication etiquette (e.g. phone, email, text, active listening), decision-making skills (e.g. prioritizing, critical thinking), communication types (e.g. formal, informal, service recovery skills), medical terminology (e.g. anatomy & physiology, surgical terminology, instrumentation), teamwork & work groups, types of work groups (e.g. quality, cross-functional), decision making & accountability (e.g. identify roles & responsibilities), task prioritization (e.g. reading the schedule, turnover, anticipating customer needs), sterile storage & inventory management, area specific safety standards, area specific safety awareness (e.g. traffic flow, hand-hygiene, safety data sheets (SDS)), ergonomics (e.g. work-flow, proper body mechanics), temperature & humidity of the work environment, standards for temperature, standards for humidity, recording & documenting temperature & humidity (e.g. frequency), corrective actions taken if not within the parameters (e.g. who to notify), preparing the work area for storage, dress code, supplies needed (e.g. carts (closed, open), rack system (closed, semi-closed, open)), work area requirements (e.g. cleaning requirements), ordering & inventory replenishment, inventory replenishment & distribution systems (e.g. periodic automated replenishment, exchange cart system, requisition 68

systems), the ordering process (e.g. computerized vs manual), identify the product (e.g. catalog numbers, item number, descriptions), unit of measure (e.g. each, box, package, case), handle inventory deficiencies (e.g. outages, substitutes, communication), receiving & inspecting inventory, proper break-out area (e.g. corrugated cardboard, external shipping containers), inspecting for integrity (e.g. what & when to check), expiration & manufacturing dates (e.g. symbols, what & when to check), stocking & rotating inventory, location of supplies (e.g. shelf/cart location, sterile supplies), shelf life policy (e.g. expiration, event-related), process for rotating inventory (e.g. first in first out (FIFO)), proper storage requirements (e.g. height, weight, distance from wall/floor, shelving), distributing sterile & non-sterile items, distribution methods (e.g. just in time, exchange cart, case cart), proper handling of items (e.g. maintain sterility), transport guidelines (e.g. closed cart, bins, dust covers, off-site transport), monitoring & tracking items distributed, high dollar items, specialty carts (e.g. code carts, emergency carts, c-section), critical items (e.g. special order, non-stock items, doctor specials, patient specific items), vendor-owned items (e.g. loaner, consignment), items organization and tracking (e.g. manual, RFID, computerized), distribution to user departments (e.g. ER, OR, clinics, ICU), loss of sterile items, handle manufacturer product recalls, common causes of waste & loss (e.g. damaged, expired & obsolete items), patient care equipment, area specific safety standards, area specific safety awareness (e.g. OSHA/blood borne pathogens, personal protective equipment (PPE), electrical safety, hand-hygiene, regulatory agencies & professional associations), equipment operation & interpret the manufacturer's instructions for use (IFU) (e.g. operator's manual), temperature & humidity of the work environment, standards for temperature, standards for humidity, recording & documenting temperature & humidity (e.g. frequency), corrective actions taken if not within the parameters (e.g. who to notify), preparing the work area for distribution, 69

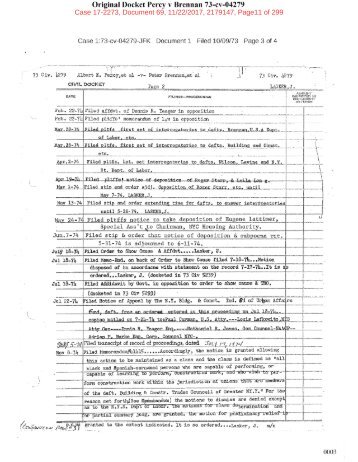

- Page 1 and 2:

THE APPRENTICE PRIVATE ATTORNEY GEN

- Page 3 and 4:

The dilemma Lincoln was facing was

- Page 5 and 6:

in the compromise of 1877 which end

- Page 7 and 8:

often unable to keep their jobs and

- Page 9 and 10:

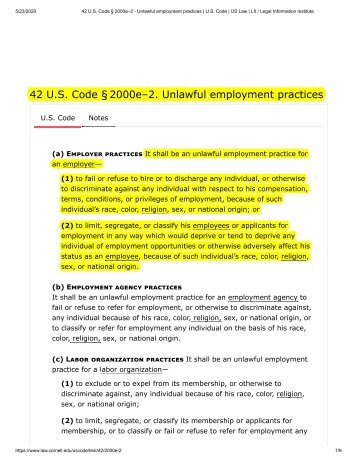

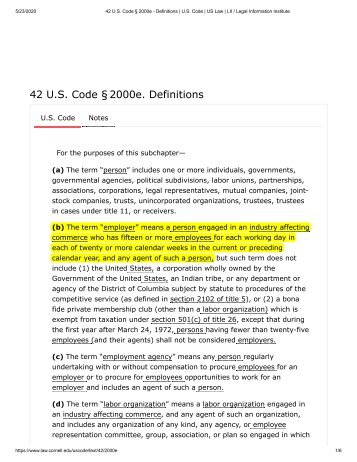

Available Less Discriminatory Alter

- Page 11 and 12:

UNITED STATES DISTRICT COURT for th

- Page 13 and 14:

accepting Defendant New York State

- Page 15 and 16:

ceased and the US withdrew from Sou

- Page 17 and 18:

compliance with the New York State

- Page 19 and 20:

A, Pt. 29 and Pt. 30. (the Fitzgera

- Page 21 and 22:

y Secretary of Labor Herman in Apri

- Page 23 and 24:

51. There are a wide variety of spe

- Page 25 and 26:

60. There are many paths of advance

- Page 27 and 28: 72. We (myself as Class Counsel, th

- Page 29 and 30: The New York State Department of La

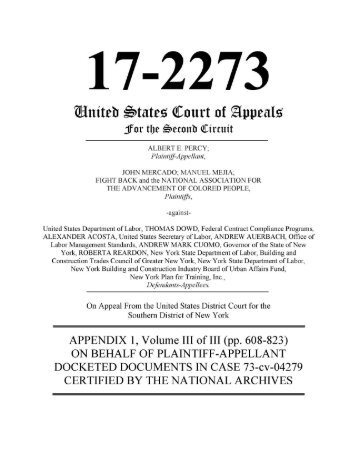

- Page 31 and 32: 04279, Appendix 1, Volume 1, page 5

- Page 33 and 34: known as the National Apprenticeshi

- Page 35 and 36: 100. The Percy Program (XVI. THE PE

- Page 37 and 38: which was done at Docket #96-104 in

- Page 39 and 40: economic and social injury and dama

- Page 41 and 42: Department as a mechanic at the Cen

- Page 43 and 44: 125. Percy was not promoted, remain

- Page 45 and 46: seek for which this action has been

- Page 47 and 48: education, skills development, trai

- Page 49 and 50: XI. The Advocates ALTERNATIVE EMPLO

- Page 51 and 52: 158. The Percy Program first presen

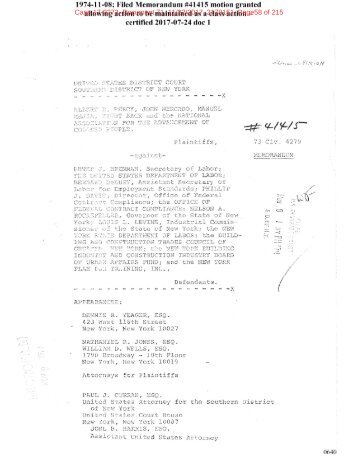

- Page 53 and 54: REGULATORY APPROVALS OF PERCY PROGR

- Page 55 and 56: on behalf of the Percy Class applie

- Page 57 and 58: The Percy Program Presented to the

- Page 59 and 60: States of America, and of rights se

- Page 61 and 62: 196. The apprenticeship program por

- Page 63 and 64: wages and lost opportunity along wi

- Page 65 and 66: 214. In Case 73-cv-04279, Percy sou

- Page 67 and 68: Percy Class when the State proffere

- Page 69 and 70: willing and able to work, , and dam

- Page 71 and 72: apprenticeship programs. The Percy

- Page 73 and 74: clean their work surfaces. Working

- Page 75 and 76: negative pressure, positive pressur

- Page 77: temperature & humidity of the work

- Page 81 and 82: decontamination work area, mechanic

- Page 83 and 84: employee information and training,

- Page 85 and 86: mitigate the hazards are emphasized

- Page 87 and 88: Lead Worker EPA 270. Lead hazard co

- Page 89 and 90: compensation carrier that is also a

- Page 91 and 92: The maximum amount that a multiple-

- Page 93 and 94: Annual Standard Premium which is as

- Page 95 and 96: of audited standard premium. Amendm

- Page 97 and 98: State’s offer of EO 45, but EO 45

- Page 99 and 100: XXVI. AS AND FOR A FIFTH CAUSE OF A

- Page 101 and 102: the availability of the singular cr

- Page 103: disenfranchised, and, pray that thi

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...